| Availability: | |

|---|---|

|

| |

Terracotta Panle, produced by moden prodution technicques, manufactured from nature clay, extrued into shapes and then fired at high temperature.It’s available in a wide range of colours, profiles and finishes.

Terracotta Ventilated facades, with high level of heat insulation and sound proofing, are known as the best solution for for modern rainscreen and sunscreen facades.

Terracotta Panel- Production Process

Large quantity raw material stock

Top brand Germany and Italy production lines

Stable quality control, large prodution capacity and fast delivery.

Nature clay treatment --Extrusion--Drying --Glazing if needed--Firing --Cutting and inspection--QC control--Packing and Delivery.

Terracotta Panel-Dimensions

Terracotta Panels are normally of a thickness of 18mm, 20mm, 25mm and 30mm 40mm. All sizes can be customized made.

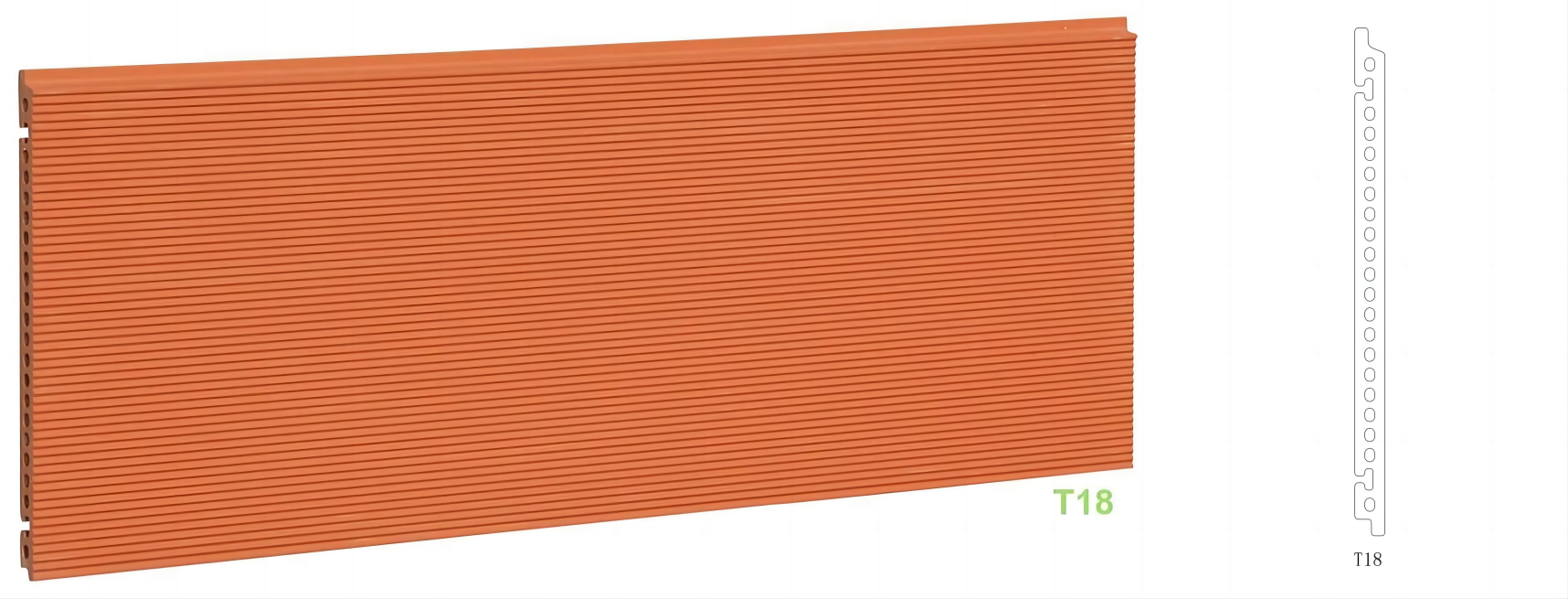

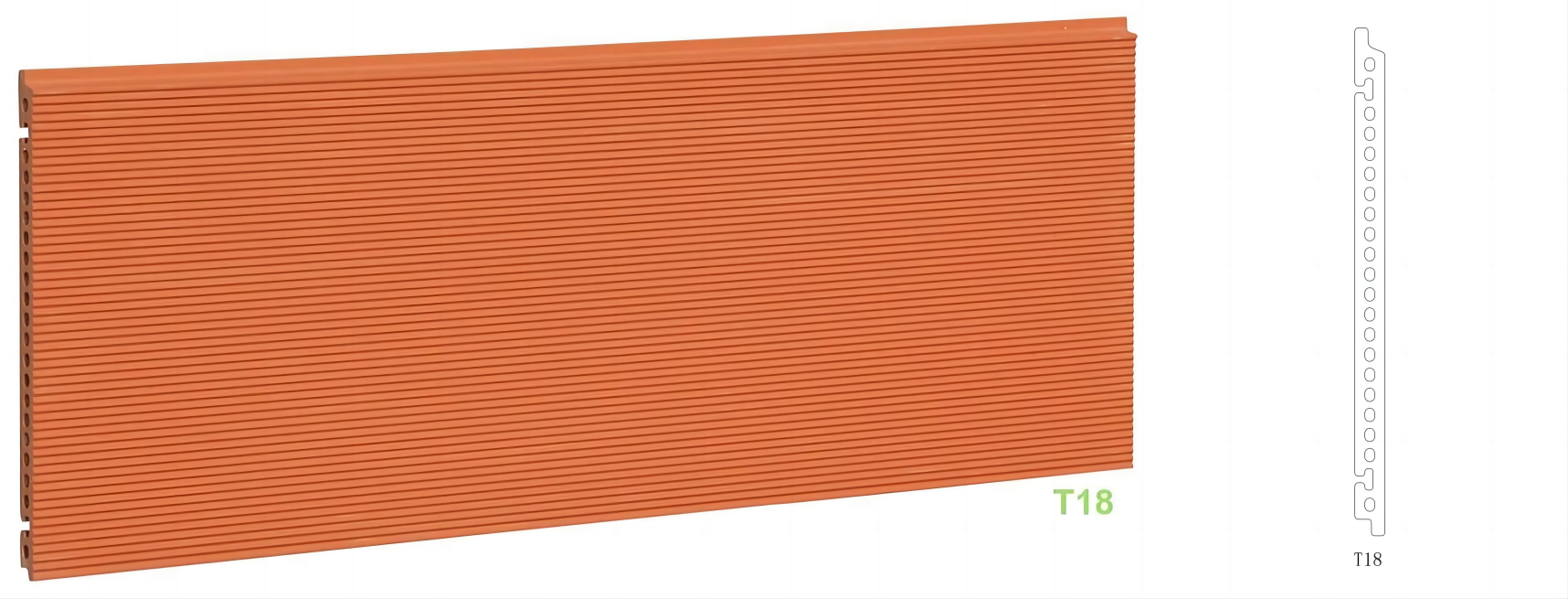

T18 series

Length: 300~1500 mm

Width: 206,306,356,406,456,506,556,606mm.

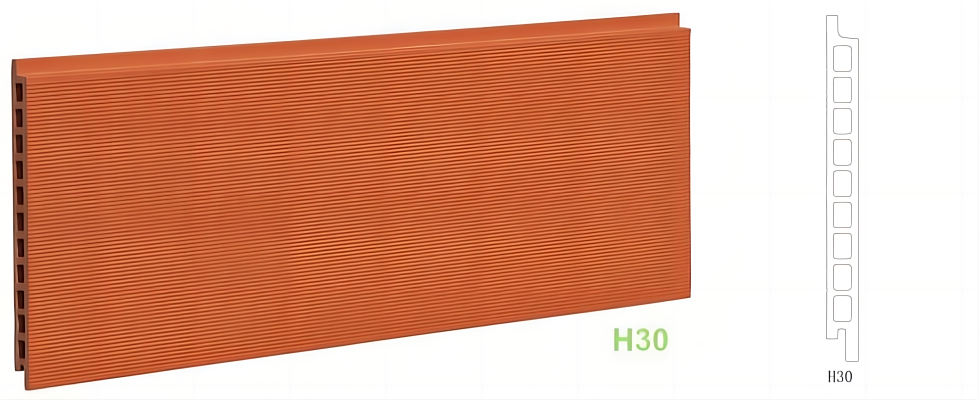

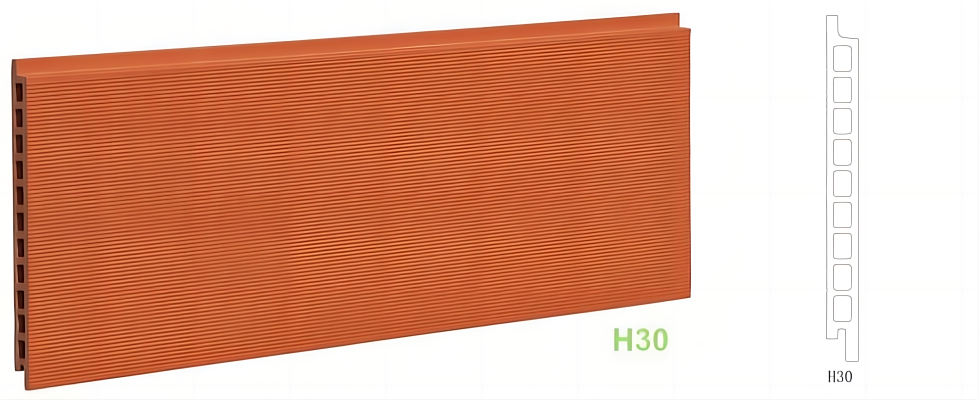

H20 H25 H30 series

Length: 300~1500 mm

Width:260,310,360,410,460,510,560,610mm

Terracotta Panel-Colors

Terracotta panel are available in more than 70 standard colors. More colors can be get by glazed.The color will be never fade.

|  |

| Brown | Grey |

|  |

| Red | Yellow |

| |

Terracotta Panel-Surface Texture

Facade terracotta panels produced with lots of different surface texture,such as natural,groove,matte glazing,glossy glazing,metallic glazing,sandblasted,and other customized finishes.Terracotta panel perfect shows different facade styles and effects for different architectural styles,and also meet architects'fully dream drawing design for different facade wall.

Terracotta Panel Technical Data

Breaking strength in N-3634 (Tested by EN ISO 10545-3:1997)

Abrasion resistance:174-205(Tested by EN ISO 10545-6:2012)

Modulus of ruptur in N/mm2--25((Tested by EN ISO 10545-4:2019)

Thermal expansion-5.8 x 10-5C-1 (Tested by EN ISO 10545-8:2004)

Reaction to fire-Class Al

Frost resistance Fully resistant (Tested by EN ISO 10545-12:1997)

Thermal shock resistance -Fully resistant(Tested by EN ISO10545-9:2013)

Water absorption-6.20%(Tested by EN ISO 10545-3:1997)

Terracotta Panel-Installation Technical

Terracotta panel's insallation system is durable aluminium and stainless steel subframing,suitable for all applications.

T18 Type Terracotta panel'sinstallation drawing

|  |

|  |

H30 Type Terracotta panel's installation drawing

|  |

|  |

Terracotta Ventilated facades,with high levelof heat insulation and sound proofing, are known as the best solution for building external facades.

More detailed information, pls contact with team.

Special Shape Terracotta Panel

|  |  |  |  |  |

|  |  |  |  |

Why Choose Terracotta Panle

100%nature caly

No Fading and non-combustible

Durable and high strength

Scratch and dent-resistant

Extreme UV and weather resistance

Environmentally Friendly

Impact Resistant but light weight

Higher thermal insulation,improved noise reduction

Terracotta Panle, produced by moden prodution technicques, manufactured from nature clay, extrued into shapes and then fired at high temperature.It’s available in a wide range of colours, profiles and finishes.

Terracotta Ventilated facades, with high level of heat insulation and sound proofing, are known as the best solution for for modern rainscreen and sunscreen facades.

Terracotta Panel- Production Process

Large quantity raw material stock

Top brand Germany and Italy production lines

Stable quality control, large prodution capacity and fast delivery.

Nature clay treatment --Extrusion--Drying --Glazing if needed--Firing --Cutting and inspection--QC control--Packing and Delivery.

Terracotta Panel-Dimensions

Terracotta Panels are normally of a thickness of 18mm, 20mm, 25mm and 30mm 40mm. All sizes can be customized made.

T18 series

Length: 300~1500 mm

Width: 206,306,356,406,456,506,556,606mm.

H20 H25 H30 series

Length: 300~1500 mm

Width:260,310,360,410,460,510,560,610mm

Terracotta Panel-Colors

Terracotta panel are available in more than 70 standard colors. More colors can be get by glazed.The color will be never fade.

|  |

| Brown | Grey |

|  |

| Red | Yellow |

| |

Terracotta Panel-Surface Texture

Facade terracotta panels produced with lots of different surface texture,such as natural,groove,matte glazing,glossy glazing,metallic glazing,sandblasted,and other customized finishes.Terracotta panel perfect shows different facade styles and effects for different architectural styles,and also meet architects'fully dream drawing design for different facade wall.

Terracotta Panel Technical Data

Breaking strength in N-3634 (Tested by EN ISO 10545-3:1997)

Abrasion resistance:174-205(Tested by EN ISO 10545-6:2012)

Modulus of ruptur in N/mm2--25((Tested by EN ISO 10545-4:2019)

Thermal expansion-5.8 x 10-5C-1 (Tested by EN ISO 10545-8:2004)

Reaction to fire-Class Al

Frost resistance Fully resistant (Tested by EN ISO 10545-12:1997)

Thermal shock resistance -Fully resistant(Tested by EN ISO10545-9:2013)

Water absorption-6.20%(Tested by EN ISO 10545-3:1997)

Terracotta Panel-Installation Technical

Terracotta panel's insallation system is durable aluminium and stainless steel subframing,suitable for all applications.

T18 Type Terracotta panel'sinstallation drawing

|  |

|  |

H30 Type Terracotta panel's installation drawing

|  |

|  |

Terracotta Ventilated facades,with high levelof heat insulation and sound proofing, are known as the best solution for building external facades.

More detailed information, pls contact with team.

Special Shape Terracotta Panel

|  |  |  |  |  |

|  |  |  |  |

Why Choose Terracotta Panle

100%nature caly

No Fading and non-combustible

Durable and high strength

Scratch and dent-resistant

Extreme UV and weather resistance

Environmentally Friendly

Impact Resistant but light weight

Higher thermal insulation,improved noise reduction